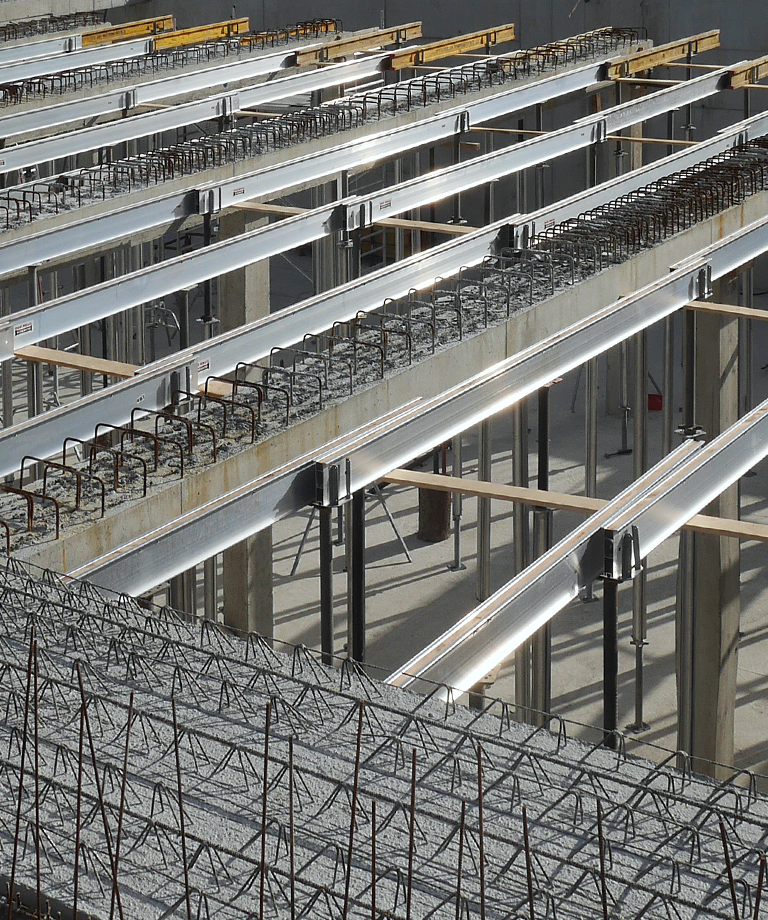

In situ downstand concrete beams and changes in soffit level present a challenge on every building site. ISCHEBECK can offer you two systems for simple, fast and economic beam forms:

- U-HV beam clamp

- UZ beam side frame

Both systems consist of just a few components. The materials used – aluminium and galvanised steel – are sturdy and durable. And their low weight means striking and relocating the forms can be carried out quickly by hand.